Engine cleaning and servicing

The Somerset Aeroplane Company carries out all aspects of engine rebuilds, repairs and maintenance. Our comprehensive step by step process alongside in-house vapour blasting enables us to perform crucial inspections to determine the serviceability and condition of your power plant with minimal delay. Whether you’re down on compression or you suspect something more serious, we are here to help you get air back under your wings. As passionate aviators, we appreciate time on the ground can be frustrating so we aim to minimise that time.

Crankcase overhauls

In our view, crankcases are a real thing of beauty. They often they appear complicated, with many apertures for different components belonging to your engine. More often than not, they are subject to lots of tactile engagements through “on board” maintenance, as a result there are many areas of a crankcase which should be monitored and reviewed.

As part of our overhaul process we cover –

Corrosion and cracking

Stud condition

Bearing faces

Fluid galleries

Surface re-facing

Dye pen inspection

Repair and replacement

Painting and finishing

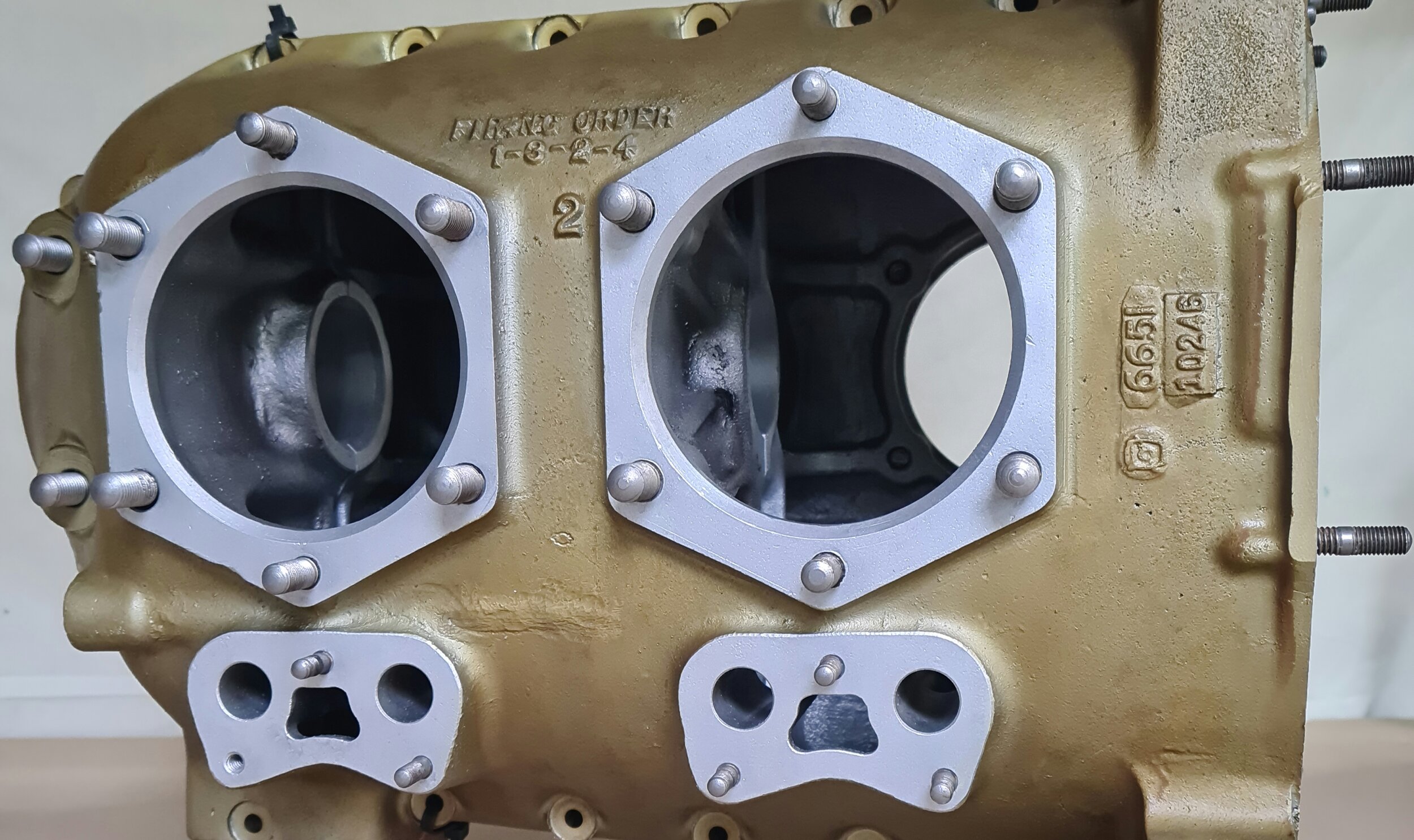

Armstrong Siddeley Cheetah IX Crankcase post paint application.

Continental C90 crankcase post wet blasting and etch priming.

Cylinder Overhauls

Cylinders are a vital part of any engine and can fail or underperform for a variety of reasons. Piston rings can be a common cause for low compression but it doesn’t stop there, a faulty valve system can also be the culprit, or much worse, a crack in your cylinder. There are many elements to a cylinder, with some being less obvious than others. Over time a cylinder can become out of round, also known as ovality, our specialist machining can rectify such a problem as long as it is within limits. Our overhaul programme will ensure that your cylinders are reconditioned to the highest standard.

We cover:

Corrosion and damage

Internal bore inspections

Re-grinding

Valves

NDT inspection

Painting & Finishing

Repair & Reconditioning

Engine assembly

As part of the overhaul schedule, the assembly process also takes place onsite with the correct tooling. Our 360 degree assembly jig allows us to rotate the engine during assembly, giving us full access to every part of your engine without damage or unnecessary stress. Our mobile jig also allows us to bench run your engine at our facility to make sure everything is operating correctly before being refitted to your machine.

Cheetah X crankshaft assembly

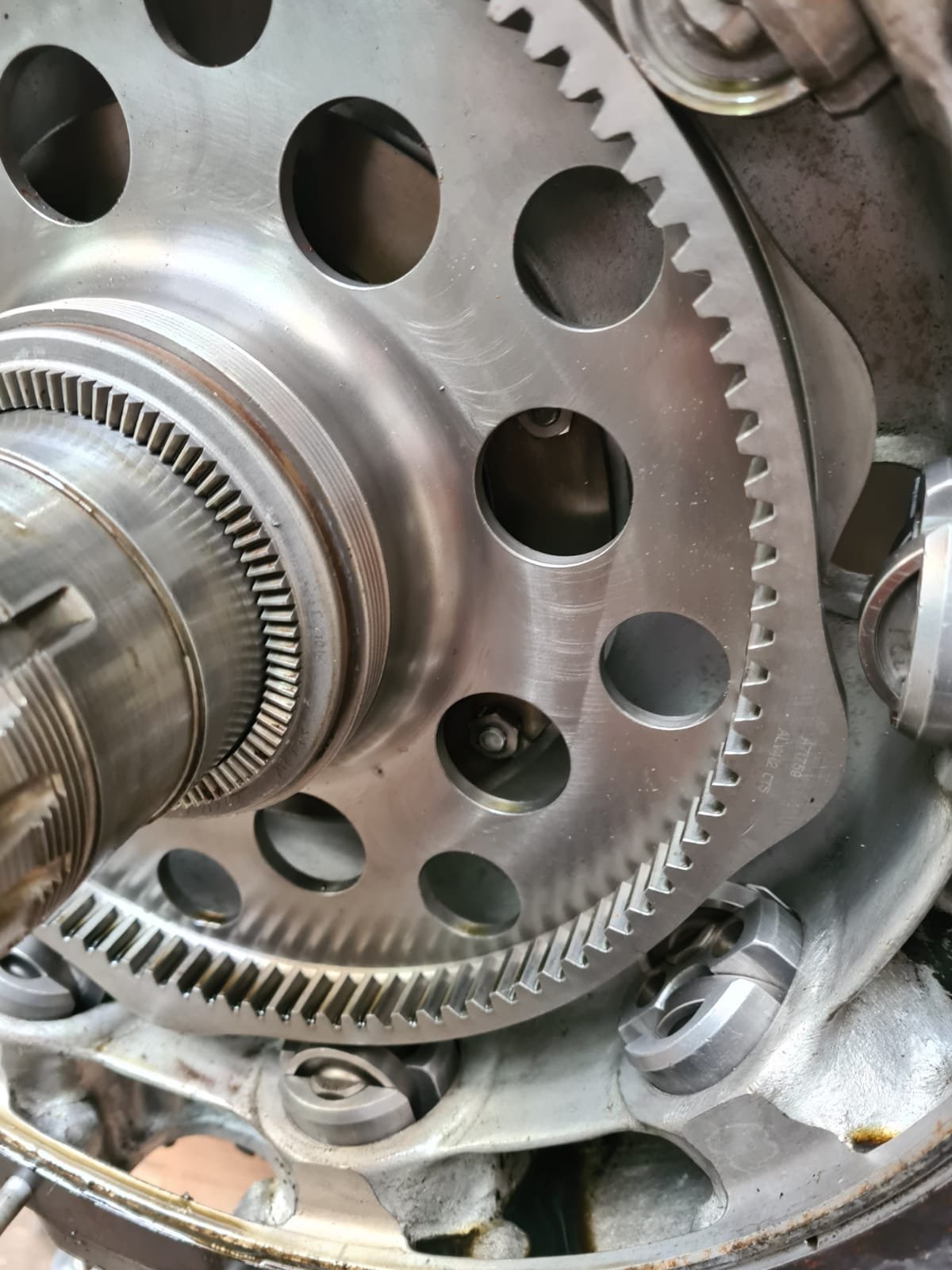

Alvis Leonides 126 cam disc

Alvis Leonides crankshaft bearing

Cheetah X cam disc assembly